A question that we are often asked about our graphene nanotechnology is, well, what exactly is it? This blog is here to help answer that question. To start, we should break down the core components used in a nanotechnology boosted ceramic coating. The first is the base of any ceramic coating, SiO2.

This is the core of most ceramic coatings. On the molecular level, it is incredibly tough and resistant to damage. When it is combined with a resin and allowed to cure, it creates a tough and scratch resistant surface. The resins will vary from maker to maker, and product to product. To this resin additives are chosen that determine other benefits such as hydrophobicity and smoothness. The selection of additives is based on what can successfully be combined without diminishing the quality of the product.

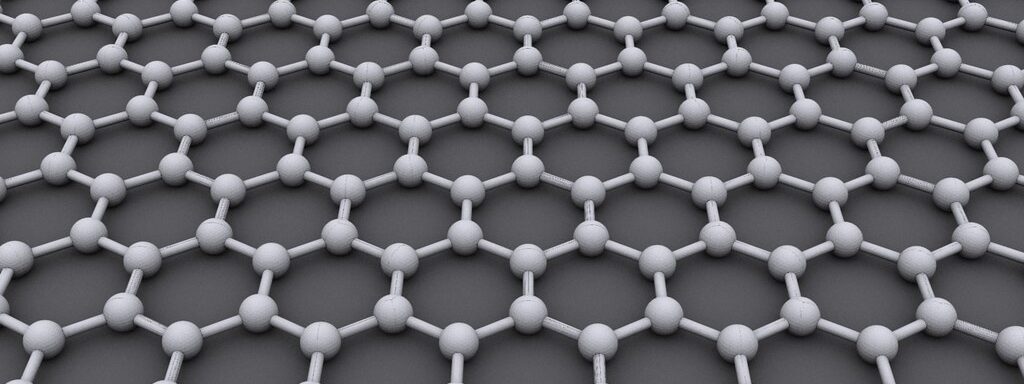

The next step is the introduction of graphene. So, what exactly IS graphene? It is a type of Carbon “Allotrope.” An Allotrope is a structure formed by the bonds between molecules. For graphene sheets, these structures are single molecule thick layers of Carbon that are formed into hexagonal lattices.

Now this is something that is often surrounded in misunderstandings and misinformation. So, let’s get a few of those out of the way. First, it is not the same material as what is in your pencil, despite being the same molecule. In a pencil, you have graphite. This material is made of layers of often hundreds of layers of graphene that have stacked on top of each other. It has different properties, and should not be used in a ceramic coating.

Second, it will not make your car as hard as a diamond. Whoever claims this is lying. Where graphene is fantastic for reinforcing a structure at a molecular level, it is not as hard as a diamond, otherwise known as the hardest substance known to humanity.

This is where the infusion process comes in. There is a misconception made that to get the desired result you would just combine graphite powder with SiO2 and apply the results. If only it were so simple. Doing this causes a few problems. Because graphite is often hundreds of layers of graphene thick, it is too large to bond at the molecular level. With poor quality products, you will find a layer of graphite that has congealed at the bottom. Even if it is mixed back into the SiO2, it will begin to sink again.

On top of that, it will start to leave small black clumps throughout when applied. Making the coating all but useless on anything but an already black car. The result is lower protection, with an unappealing look that will devalue your car, and most likely damage it. Especially if the clumps of graphite scrape against the paint during the application process.

A proper infusion is a chemical process that makes the molecules bond together at the molecular level. What happens during this process is the graphene bonds with the SiO2 and reinforces it at the molecular level. The result is that when the coating is curing, the bonds that would typically form are strengthened. Imagine it like rebar inside cement. Without it the cement is already strong. But with it, it can handle greater forces.

So, all of this aside, what about the stories of people getting graphene infused ceramic coatings that barely protect their cars? From what we can tell, where the manufacturers have successfully bonded the graphene to the SiO2, their formula was not fit for purpose to begin with. This is largely due to the choice of additives. As mentioned before, they can sometimes conflict, and the trick to a good coating is making sure that all of the ingredients properly adhere to each other without diminishing their properties. Unfortunately, some manufacturers try to mix too much together into a single formula without proper testing, and the result is inferior products.

Hopefully this has helped clear up just what manufacturers mean when they say “graphene nanotechnology” when referring to their ceramic coatings. Where the technology is new, it sets a new standard for ceramic coatings, and will keep cars shining for years to come.

Image courtesy of CORE-Materials